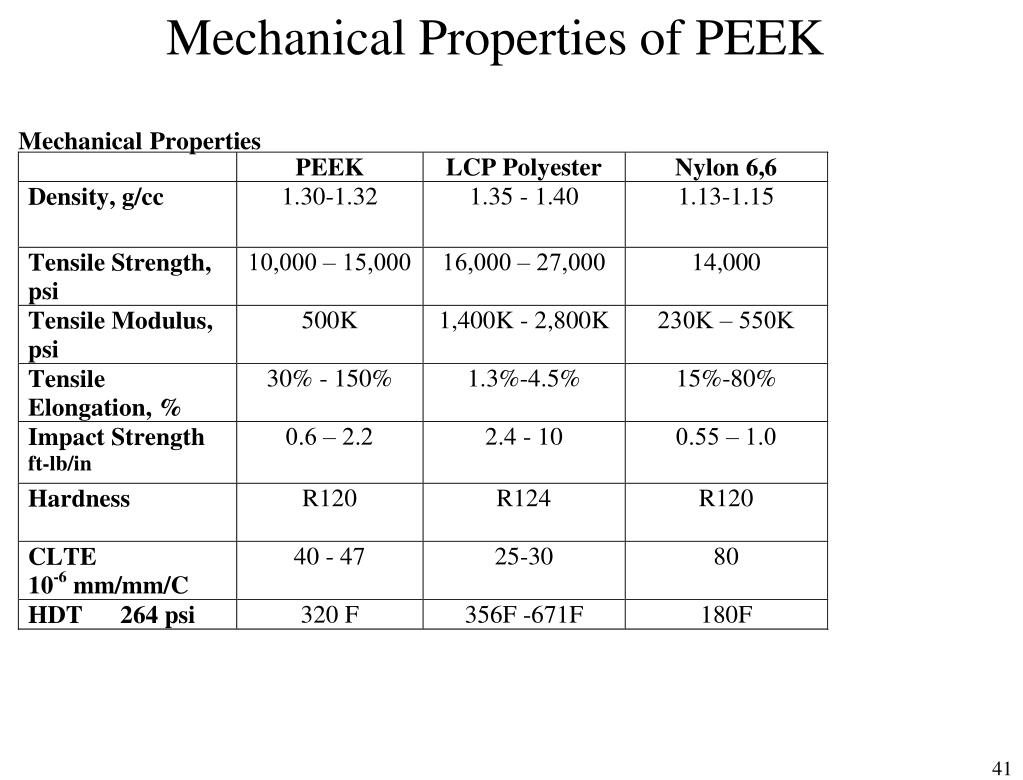

Some of the properties of 450G and 150G are compared in the table below to illustrate these differences. PEEK is a popular material because of its combination of good mechanical behavior in terms of strength, toughness, creep and stiffness. This is a consequence of the shorter polymer chains, which are less entangled, crystallise more readily and to a greater overall extent. However, the lower molecular weight also changes the bulk properties of the polymer: lower molecular weight PAEKs have higher stiffness and strength combined with reduced toughness, ductility and impact resistance. As a result, 150G may be more suitable for applications where lower viscosity in the melt during processing is desirable, for example, when injection moulding thin-walled parts or long, thin sections with intricate geometries impregnating carbon or glass fibres for composite prepregs or adding high levels of solid fibrous or particulate fillers and reinforcements to make compounds. VICTREX PEEK 150G is a higher flow, lower molecular weight, lower MV grade of PEEK compared to 450G. Other VICTREX PEEK grades are available with higher and lower melt viscosities and higher or lower molecular weights respectively. There are always materials for you.VICTREX PEEK 450G is defined as a standard melt viscosity (MV) PEEK grade, with a medium molecular weight. The plastic material size we provide could cover a really wide range. Keward plastics could offer you PEEK rods, sheets, tubes, and machined components. PEEK other propertiesįor PEEK shows these great properties, nowadays it is gradually widely used in many industries. PEEK has great chemical resistance properties, for the common chemicals, only 4 kinds of acids and bases could corrode PEEK.įor more PEEK chemical resistance performance, please check here. So the material is often used as a radome in military applications. It has one of the highest levels of heat resistance and. According to some research, the ratio of wave permeability of PEEK is beyond 95%. PEEK polymer is a high performance plastic material with an excellent balance of physical properties. Meanwhile, PEEK plastic also exhibits very great wave permeability. The material’s dissipation is low and the dielectric constant is very stable, so these characters make the PEEK is widely used in the electrical connector industry, especially in high-frequency connectors applications. PEEK is a high-performance plastic with great electrical performance.

Due to its mechanical strength and lightweight, PEEK could be used in many applications to replace metal.

PEEK plastic physical and strength propertiesĪs we can see from the data, PEEK shows great mechanical strength and it is a plastic that combines rigidity and toughness. PEEK belongs to the field of Peek plastic and polymer materials, its material composition, chemical properties, organization and morphology determine it can improve intergranular corrosion, improve corrosion resistance, corrosion resistance and nickel steel are similar. Applications requiring strength and stiffness as well as high ductility.

#PEEK MATERIAL PROPERTIES SERIES#

PEEK is a plastic that combines all those characters. PolyEtherEtherKetone (PEEK) is a strong and stiff material that is used in applications that require great performance at elevated temperature ranges.PBYs PB30000 series materials are used in areas such as automotive, aerospace, oil and natural gas, electronics, and FDA suitable environments. The material requirements of the industry are high-temperature resistance, very good mechanical strength, and excellent insulation performance. We can see many PEEK plastics are used in the oil logging technology as the insulation components. PEEK is also the most widely used high thermal stable plastic.

One of the most important characters of PEEK plastic is its exceptional high continuous working temperature. The glass transition temperature is 150℃.PEEK is a high-performance, semi-crystalline plastic which shows many unique properties. 9 min read Polyether ether ketone (PEEK) plastic is a highly coveted engineering material, thanks to its superb blend of strength, resistances, and workability.

0 kommentar(er)

0 kommentar(er)